We have a range of production facilities to manufacture a wide range of products in bronze and confer high added value on them.

They are detailed below:

SMELTING

| |

We have 5 INDUCTOTHERM induction furnaces:

- 1 furnace of 1500 kg

- 4 furnaces of 500 kg

Induction technology is undoubtedly the most efficient, competitive and environmentally friendly of all existing smelting processes.

MOULDING AND CASTING

We use metal moulds of our own design, which do not generate any additional cost to our clients, as we maintain ownership of them.

The casting process is carried out exclusively by centrifugal casting, a process that combined with the metal nature of our moulds, confers the most demanding properties on our products.

We only cast ingots and shavings from our own machining.

To carry out this procedure, we have a wide range of centrifuges that are detailed below:

- 1 individual centrifuge up to Ø 2100 mm

- 1 individual centrifuge up to Ø 800 mm

- 1 dual centrifuge up to Ø 600 mm

- 1 carrousel with 50 centrifuges

- 5 linear tables with 10 centrifuges per table

- 8 centrifuges for bars of Ø 30 mm up to Ø 125 mm (maximum length: 550 mm)

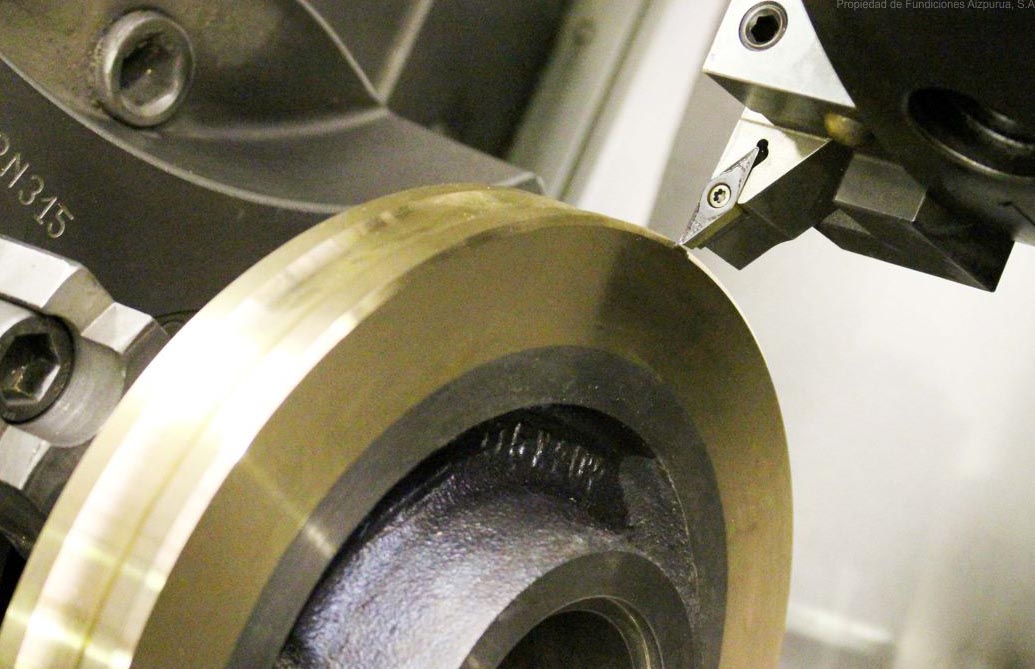

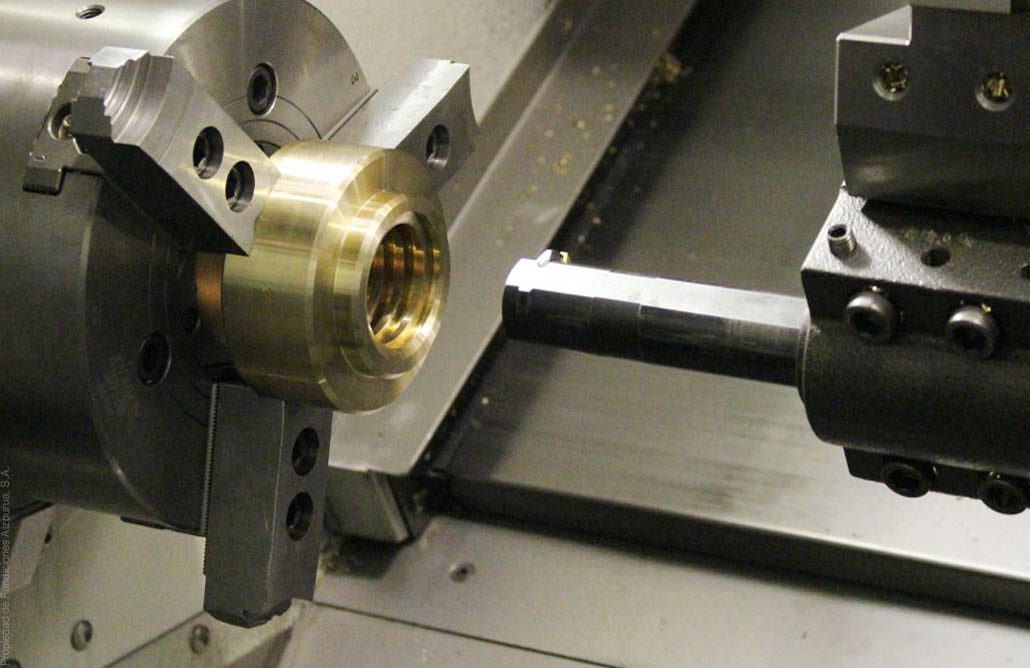

MACHINING

We also have other machining equipment, which is detailed below:

| |

- 1 CNC vertical lathe Ø 2100 mm

- 1 front facing lathe Ø 1500 mm

- 11 conventional parallel lathes from Ø 300 to Ø 1000 mm

- 5 CNC lathes for finishing pieces

- 1 milling machine

- 1 slotting machine

- 1 bar boring machine Ø 60 mm

- 2 transfer drills

PRODUCTION CAPACITY

- Maximum diameter: 2100 mm / 80 in

- Maximum height: 1100 mm / 43 in

- Maximum gross weight: 2400 kg / 5290 lbs

GROSS SMELTING CAPACITY

- Tin bronze: 2000 t/year

- Aluminium bronze: 200 t/year

- Heavy-duty brass: 100 t/year